Goebel integrated the Müller Martini printing machines division, which fits perfectly into the Network & Partnership Strategy of the company group, bringing together all kind of printing industry competencies of small and flexible autonomous companies under one Swiss Holding, Goebel Capital.

The Goebel Print Competence Center for final assembly, commissioning, training and conference purposes has been opened in Eschenbach, Switzerland, as platform and “meeting point” for customers and industry partners.

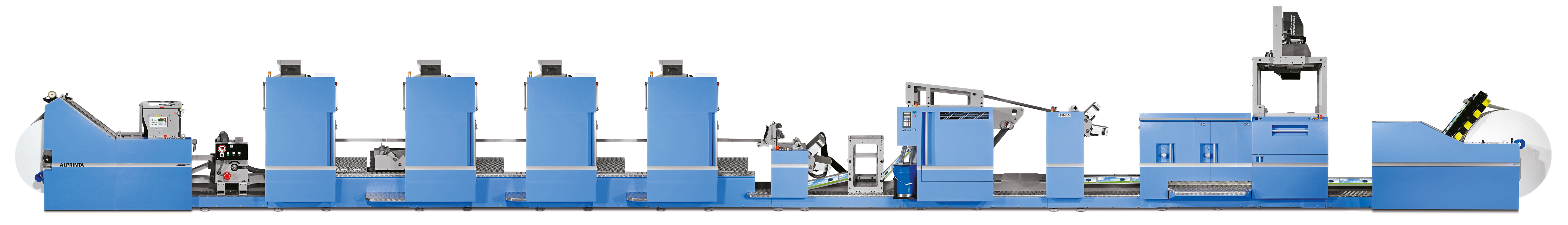

Relaunch of the Concepta and Alprinta series within the new Goebel portfolio.