Goebel produces web-fed printing machines for the two growing market segments of security printing and packaging printing – including label printing. German engineered and Swiss made to the highest standards, Goebel has been meeting customers' needs for 170 years.

The VSOP technology (Variable Sleeve Offset Printing) as well as the special security printing technologies, letterset and true rainbow printing with a double ink fountain come from Goebel.

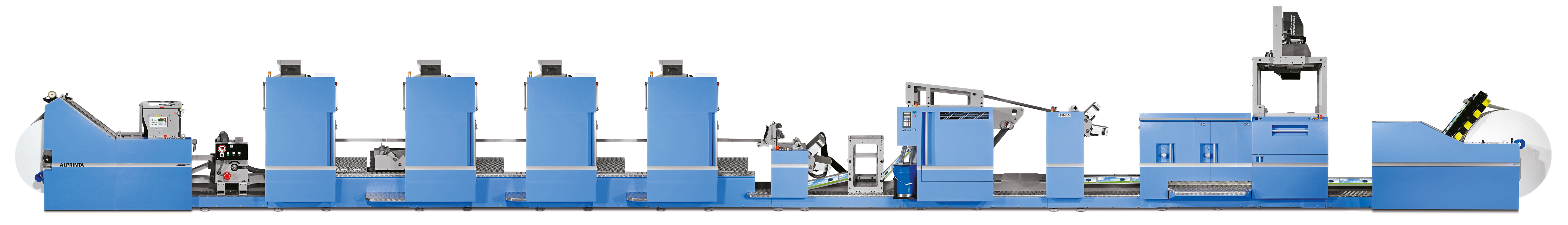

Alprinta

Substrates: Paper, Label material, Film

Substrate range: film: 10μ - 350μ, paper: 28-250g/m2

Web width: 520, 740

Size range: film: 20" – 28 1/3", paper: 17" -36" on special request up to 40"

In increments of 0.1 mm, 1/3" or 1⁄4" or 6mm as special option

Printing technologies: Offset printing: based on size variable cassettes: VOI = variable offset insert, with separate servo driven plate & blanket cylinder, light weight format cylinders can be exchanged manually and tool less. 3 cylinder gear driven offset cassettes

Flexo printing: Flexo unit with anilox and cliché sleeve for UV, water or solvent based inks plus integrable aggregates: silk screen & gravure printing, inkjet

Processing cassettes: die cutting, cross perforation, sprocket-hole – and file-hole punching

Converting mode: reel to reel, reel to sheet, reel to fold

Curing technology: UV; EB curing; hot air for water or solvent based inks

Drive system: servo drive

Applications: commercial work, mailings, security printing, pharma printing, labels, covers, packaging

OEM equipment: remote ink key control, register control system, web video system,100% inspection,silk screen unit, gravure unit, Inkjet

For more details, click Alprinta Brochure

For other languages, click French, Italian or Spanish

Concepta

Substrates: Paper, Label material

Substrate range: 28 – 250 g/m² (web length zero: 40-170 g/m2)

Web width: 520

Size range: 14" – 28 1/3" (special sizes on request)

Printing technologies: based on size variable cassettes: wet offset-, waterless offset and flexo printing; numbering, letterset as well as integrable aggregates: flexo printing, silk screen printing, inkjet

Processing cassettes: die cutting, cross perforation, sprocket-hole – and file-hole punching

Converting mode: reel to reel, reel to sheet, reel to fold

Curing technology: UV

Drive system: shaft driven

Applications: traditional printing, mailings, security printing, pharma printing, labels, tickets, advertising supplements, forms and sheet products (A4)

OEM equipment: remote ink key control, register control system, web video system, 100% inspection, silk screen, flexo, Inkjet

For more details, click Concepta Brochure

For other languages, click French, Italian or Spanish

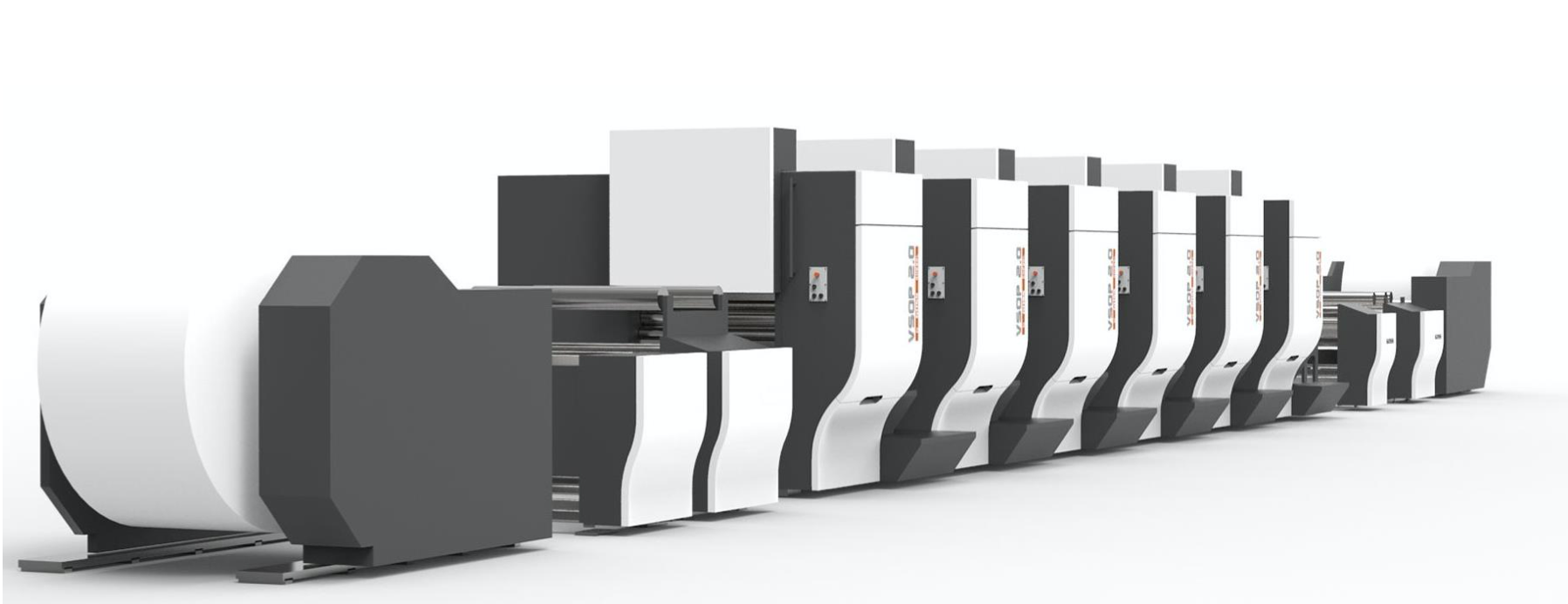

Novaprint

Substrates: Label material, Film, Paper, Cardboard

Substrate range: 50μ - 250μ (special range on request)

Web width: 520, 680, 760

Size range: 17" - 28" (special sizes on request)

Printing technologies: offset printing based on size variable cassettes, plus flexo printing, silk screen printing, gravure printing

Processing: die cutting, cross perforation, sprocket-hole punching

Converting mode: reel to reel, reel to sheet, reel to fold

Curing technology: UV, (EB curing on request)

Drive system: servo drive

Applications: traditional printing, security printing and high quality applications

OEM equipment: remote ink key control, register control system, web video system, 100% inspection, closed loop color control

For more details, click Novaprint Brochure

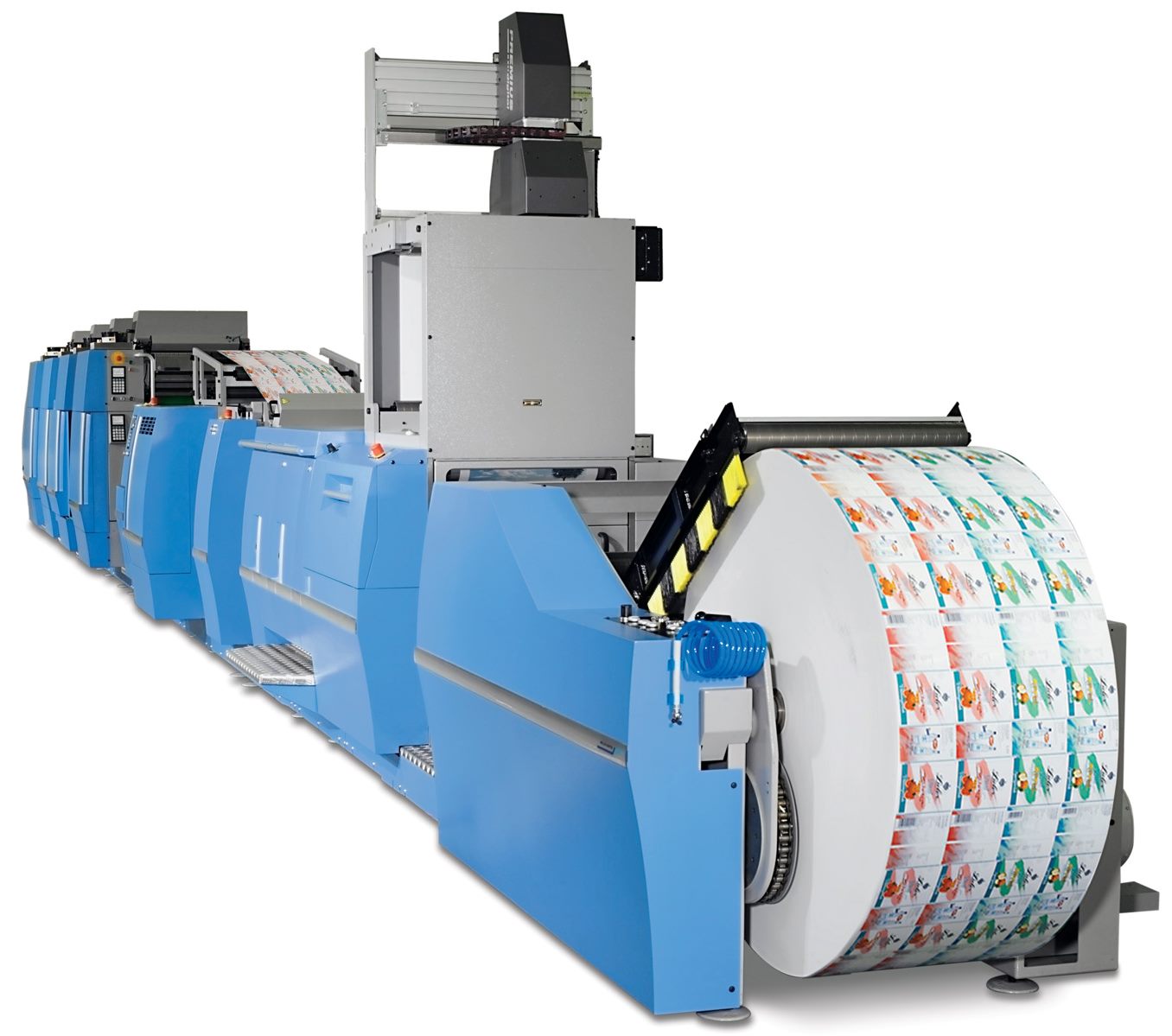

VSOP

Substrates: Film, Paper, Cardboard (optional)

Substrate range: 12μ - 300μ, 200 μ ...760 μ

Web width: 520, 850

Size range: 381...762mm / 15...30"

In increment of: infinity size variable

Printing technologies: Offset printing: based on tool less changeable plate & blanket sleeves, Flexo printing: based on tool less changeable anilox and cliché sleeves plus integrable aggregates: silk screen & gravure printing, inkjet

Converting mode: reel to reel, reel to stack with integrable die cut & stacking unit

Curing technology: UV; EB curing; hot air for water or solvent based inks

Drive system: servo drive

Applications: flexible packaging, labels, shrink sleeves; food packaging

optional card board: liquid packaging, folding boxes

OEM equipment: remote ink key control, register control system, web video system, 100% inspection

For more details, click VSOP Brochure

For other languages, click French, Italian or Spanish

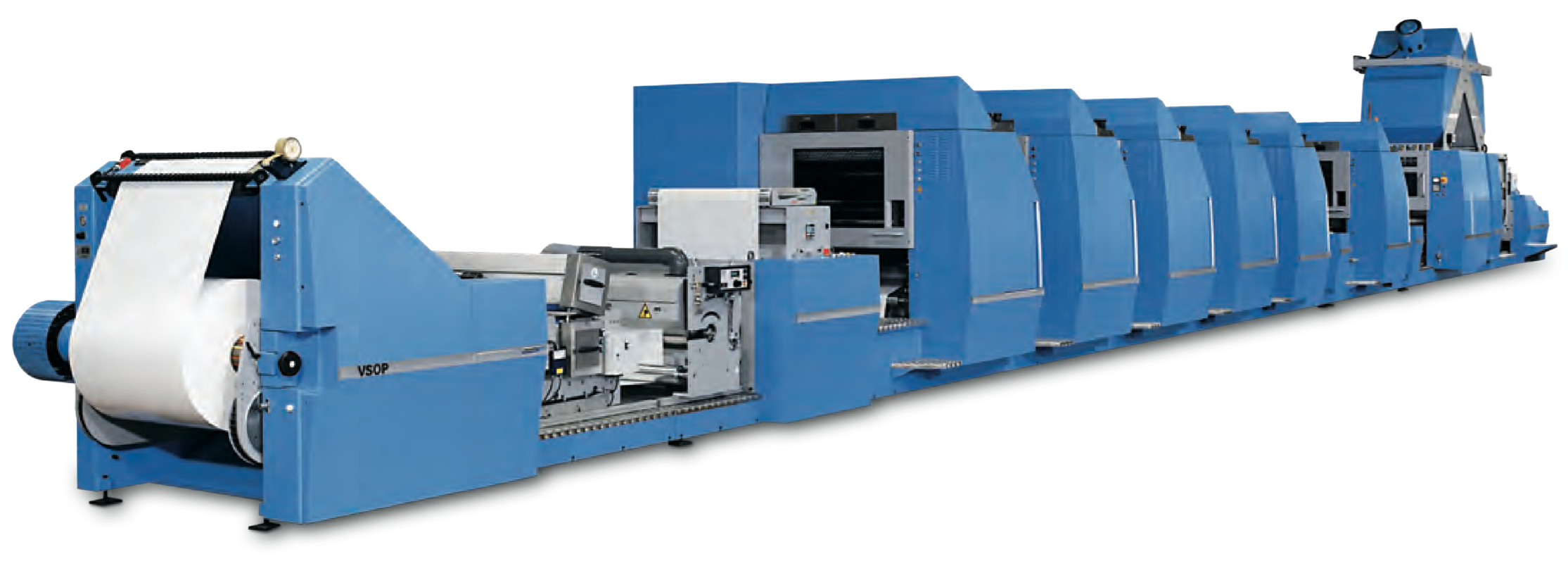

VSOP 2.0

Substrates: Label material, Film, Paper, Cardboard

Substrate range: 10μ - 700μ (depending on design)

Web width: 430, 520 and 850, 1050, 1250

Size range: 16" - 36" (depending on design)

Printing technologies: variable sleeve offset printing, plus flexo printing or gravure printing

Converting mode: reel to reel

Curing technology: UV or EB

Drive system: servo drive

Applications: labels, flexible packaging, cardboard

OEM equipment: remote ink key control, register control system, web video system, 100% inspection, closed loop color control

For more details, click VSOP 2.0 Flyer

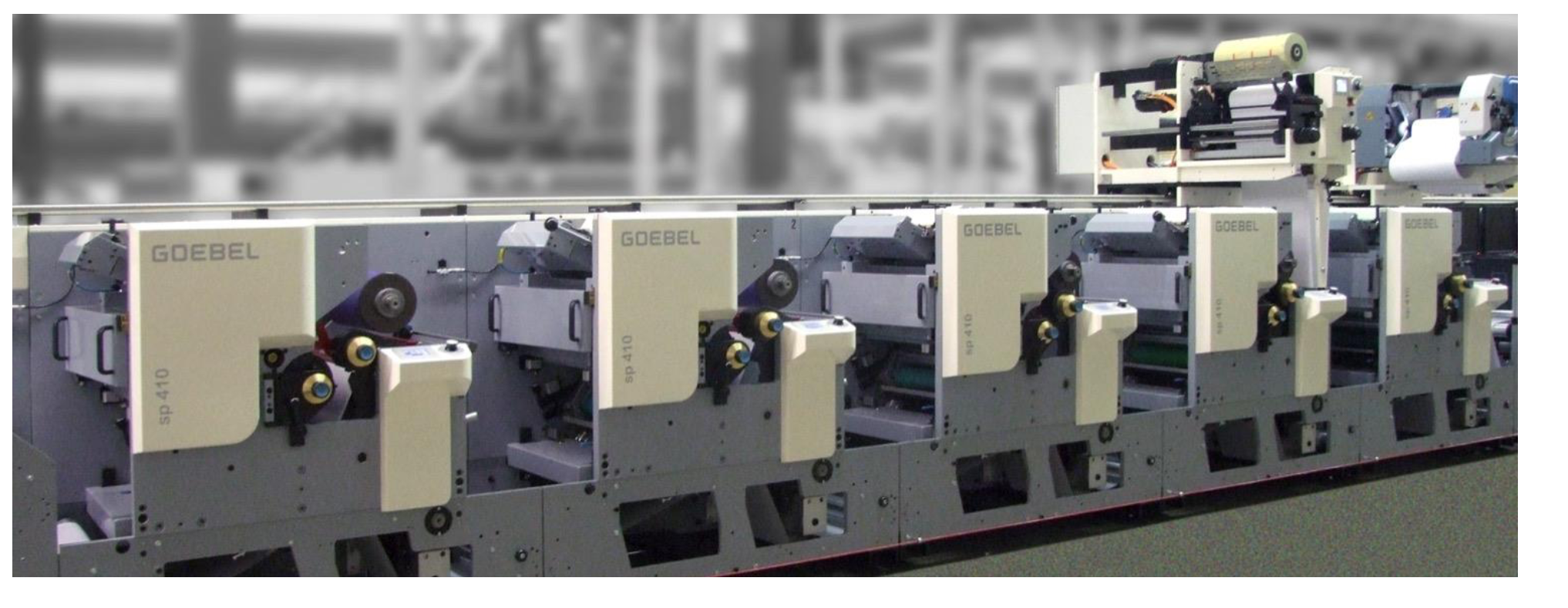

Goebel SP

Substrates: Film, Paper, Cardboard (optional)

Substrate range: 10 – 450μm

Web width: 430,520

Size range: 18 – 25”

Printing technologies: variable sleeve offset printing, letterset, flexo on rail, silk screen on rail, cold foiling on rail, additional units: flexo printing, hot foiling, etc.

Converting mode: reel to ..reel/sheet

Curing technology: UV

Drive system: main shaft / servo drive combination

Applications: postal stamps, tax stamps, visa stickers and security documents.

Unique features:

- True rainbow printing

- Minimum set-up time

- No intermediate cleaning

- EXL offset with “Y-type ink flow”

- Multi-purpose press

- CIP 4 Link

Goebel Novafold 865

The Goebel Novafold 865 paper processing line is based on the manifold proven Goebel dataforma 865 series technology. This unique Goebel design ensures constant web draw and optimum zigzag folding quality, even with critical substrates at high production speed. Consequently, Goebel is able to guarantee maximum productivity, minimum waste and lowest down time. Please use this link to give us details of your requirements, click here.